tensile testing machine procedure

The important part of the specimen is the gage section. They are used to characterize the.

To Perform The Tensile Test For Ductile Brittle Materials And Observe The Necking Lab Session Studocu

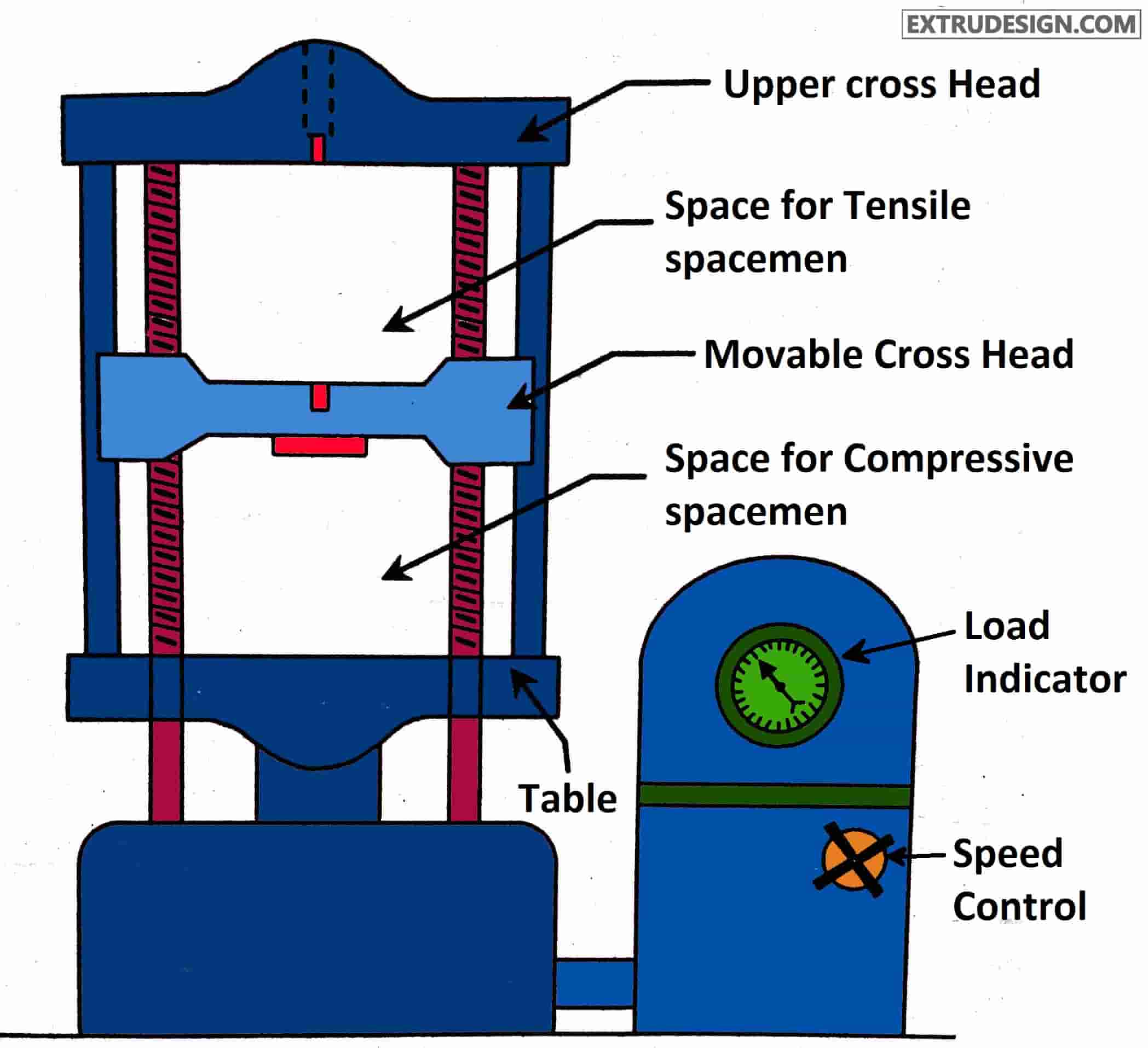

Tensile tests are typically conducted on electromechanical or universal.

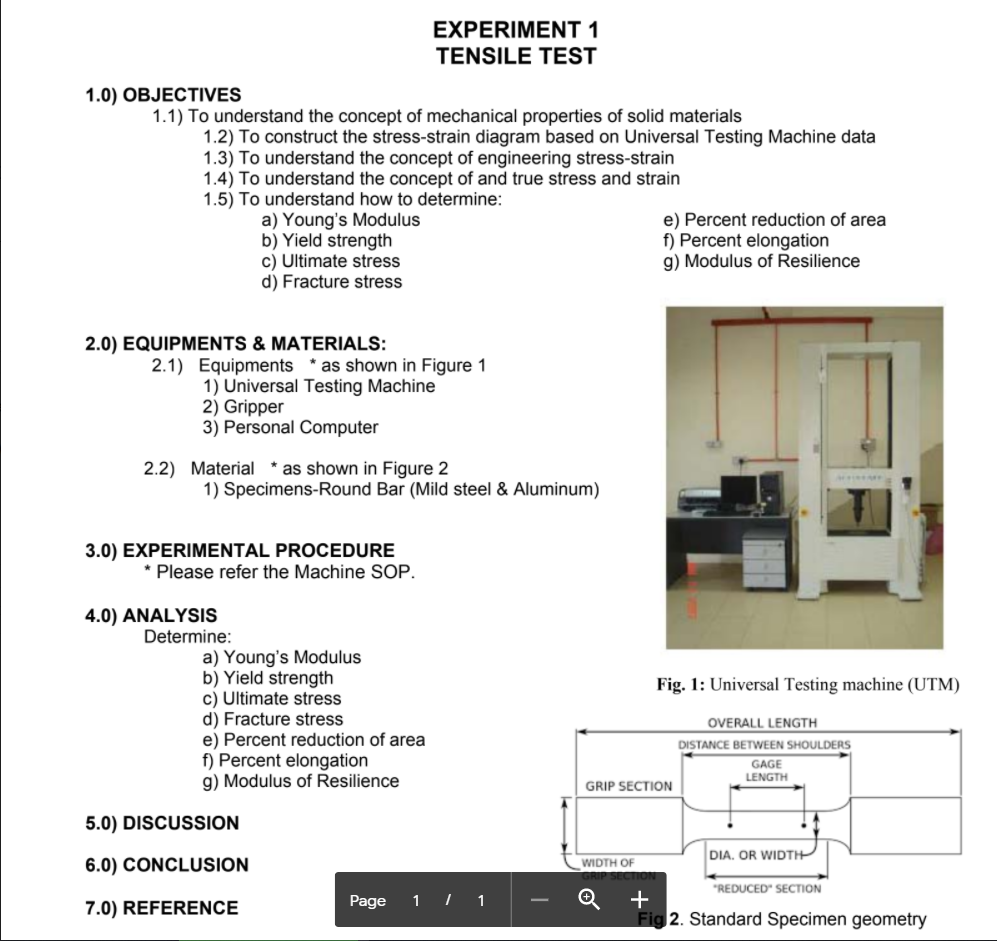

. The purpose of the tensile test is to determine one or more strength eg tensile strength Yield strength and deformation percentage elongation or reduction in area properties in compliance with certain conditions eg. The test is made by gripping the ends of a suitably prepared standardised test piece in a tensile test machine and then applying a continually increasing uni-axial load until such time as failure occurs. During the tensile test the force and extension of the specimen are measured.

The tensile test comes under the destructive test where we apply the gradually increased load up to the material to get a fracture. Other material parameters may be determined through tensile strength testing such as. A tensile testing machine performs the most fundamental and common types of mechanical testing.

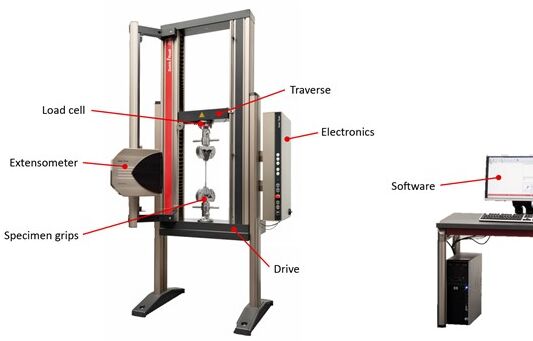

The basic idea of a tensile test is to place a sample of a material between two fixtures called grips which clamp the material. We then begin to apply weight to the material gripped at. The material has known dimensions like length and cross-sectional area.

At first set load pointer at zero by adjusting the initial setting knob then dial gauge and specimen is fixed to UTM for measuring elongation of small amounts. For isotropic materials or materials that are uniform in all axes the most common tensile test procedure is the uniaxial tension test which measures tensile test across one distinct axis of the sample. Tension test is performed on mild steel tor steel and high tensile steel to determine the properties like Youngs modulus ultimate strength and the percentage elongation.

Tensile Testing is a form of tension testing and is a destructive engineering and materials science test whereby controlled tension is applied to a sample until it fully fails. Tensile testing is used to find the behavior of the material when it is subjected to a slowly applied tensile load up to when the material gets a fracture. So a tensile test is a static test as a sub-classification.

Standard Working Procedure of Tensile Testing Machine. To operate the testing machine efficiently first of all take a piece of rubber specimen which you want to test. These accessories can be made compatible by TestResources to match test machines supplied by other manufacturers.

Influence of Test Speed. Go to the computer. Consider the typical ten-sile specimen shown in Fig.

In the tensile test a material specimen is strained until it breaks. The test involves loading a sample with a well-defined shape along the axis in tension generally to fracture and recording the resultant load and displacement to calculate several mechanical properties. Tensile testing machine has been set up to make simulated stresses as alike as possible to stresses underwent by warp yarns during the weaving.

ASTM E8 describes tensile testing of metals such as steel or metal alloys. Chapter 3 Uniaxial Tensile Testing Chapter 4 Tensile Testing Equipment and Strain Sensors Tensile Specimens and Testing Machines Tensile Specimens. A tensile test applies tensile pulling force to a material and measures the specimens response to the stress.

Procedure Of Tensile Test Machine are available as part of a TestResources product line of test machine accessories that include a wide range of test fixtures high low temperature chambers furnaces tensile grips and extensometers. Influence of Tensile Test Equipment. At the top of the main window right click on the mouse while placing the mouse cursor on the Force button located at the top of the main window and select zero option.

This will be indicated by a beeping sound. Basic principle and practical procedure of the tensile test on ductile metallic materials - Testing machine Inspekt 200 kN Hegewald Peschke Meß- und Prü. It is used to find out how strong a material is and also how much it can be stretched before it breaks.

The applied strain rate must be low so that the result is not distorted. Next to hardness measurement tensile tests are one of the most frequently performed tests in mechanical materials testing. Influence of the lengthening on resistance variations speed of lengthening maintain time at maximal lengthening and a repetitive cycling.

Measure the diameter of the test piece by vernier caliper at. The equipment arrangement and procedure for conducting the tension test on steel rod are. To study the tensile strength of a given material they also make use of a load cell along with the machine.

Wait for the machine to return the force to zero. It has enlarged ends or shoulders for gripping. In the tension test a steel rod is subjected to tension load by the means of a Universal testing machine UTM.

4141 Yarns testing procedure. By doing this tensile tests determine how strong a material is and how much it can elongate. Ad Materials Testing Machines from 1000 to 100000 pounds force.

E8 tensile tests determine the ductility and strength of various metals when the materials undergo uniaxial tensile stresses. Room temperature or elevated temperature as specified in the test standards or code. Tensile testing Procedure experiment.

This is one of the most common mechanical testing techniques. Now cut the sample in a standard shape says in a form of a dumbbell. Now clamp the specimen onto the machine by fixing the two ends of the sample on the upper jaw and lower jaw.

Test pieces are standardised in order that results. The test report can be used to determine such parameters as Youngs Modulus yield strength ultimate strength elongation at break and Poissons ratio for a sample. 24 Starting Tensile Test 1.

Following parameters have been tested. This test determines important mechanical properties such as yield strength ultimate tensile strength elongation and reduction of area. Tensile testing characterizes the forming and structural behavior of sheet metals.

Experts use tensile testers to determine the materials tensile strength.

Solved Experiment 1 Tensile Test 1 0 Objectives 1 1 To Chegg Com

Tensile Test Specimen Figure 3 Universal Testing Machine Procedure For Download Scientific Diagram

Tensile Test Specimen Figure 3 Universal Testing Machine Procedure For Download Scientific Diagram

Universal Testing Machine Procedure And Calculation Tensile Strength Yield Test Youtube

Tensile Testing An Overview Sciencedirect Topics

Astm D2370 Organic Coating Tensile Testing Admet

Tension Testing Tensile Testing Admet

Schematic Diagram Of Tensile Testing Machine Download Scientific Diagram

Universal Testing Machine Components And Functions The Constructor

Tensile Testing Machine And Tester Zwickroell

Universal Testing Machine Construction And Working Principle

Tensile Test On Utm Machine How To Perform Tensile Test Tensile Test Full Detail ह न द Youtube

Tensile Test Specimen Figure 3 Universal Testing Machine Procedure For Download Scientific Diagram

Tensile Test Screw Testing With Universal Testing Machine 250kn Youtube

Din En Iso 6892 1 Tensile Test On Metals Zwickroell

Tensile Testing Machine 5 Download Scientific Diagram

Universal Testing Machine Utm Working Explained Tensile Test Along With Stress Strain Curve Youtube